So, you have heard about how great 3D printing is and want to apply it to your business model. How can you tell that this manufacturing is perfect for you?

Additive manufacturing can help your business, but it can be truly helpful only if you use it in the right way. Using 3D printing as a strategy can be an asset, but that does not apply to all. A well-planned 3D printing can help you reduce costs, build better products, optimize the whole production process and ultimately reduce costs.

How do you know when it is better to use 3D printing or not? In this article we has compiled the best tips to identify 3D printing opportunities.

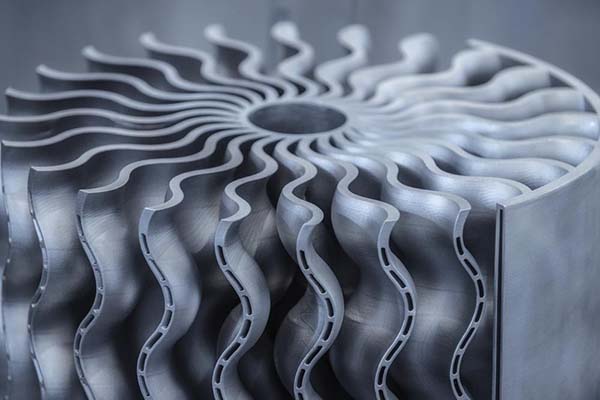

3d printed turbine blades*

Things to Know Before Implementing 3D Printing

Check which part of the manufacturing process will take longer

In the manufacturing industry, time is of the essence and the faster a product can be produced, the better. The beauty of 3D printing is it can hasten the process in several ways. For instance, it does not need tooling. It is faster to produce a part without waiting for the mold. The only critical part is to evaluate your needs and see if 3D printing can satisfy them.

Configure your manufacturing line to accommodate 3D printing

Efficiency is always the key to great results, and in manufacturing, a configured production line will maximize its productivity. However, to achieve this, the process has to go through several iterations.

Using 3D printing through these iterations can help hasten the process. To use 3D printing, the first step is to evaluate the least efficient processes in configuring the line. Next is to see if it can be modified and applied with 3D printing.

Check which parts are not optimally designed because of manufacturing constraints

There are always some constraints when using any manufacturing technique. That is a given and always impacts design. Sometimes it is not a big deal, but there are times when the designer has to compromise the design because of it. This is usually the case with subtractive manufacturing.

With 3D printing, you can push the design a little bit further and overcome the limits. Thus, you need to evaluate the design and check if 3D printing can give you the expected results.

Evaluate which part has the highest manufacturing cost

Cost is important in deciding the type of manufacturing strategy to use. What if you can dramatically lower the cost of production if you change the manufacturing technique you are using?

3D printing is cheaper, but its use will still depend on the design. What you should do is evaluate the design and see if the technology is a viable option.

Possibility of combining 3D printing with other technology to optimize workflow

Here is something that can optimize your workflow: adopting 3D printing with other manufacturing techniques like CNC machining. Combining the two technologies can improve the efficiency of your whole manufacturing process.

For example, for low volume manufacturing of complex parts. 3D printing can handle this parts, while CNC machining can be used for simple parts. By combining these two, you will have an agile workflow that can easily adapt to your evolving needs.

Conclusion

These tips are not enough to cover the full implementation of additive manufacturing for your business needs. The experts at Going Rapid are ready to answer all your 3D printing questions. Contact them now for more information.