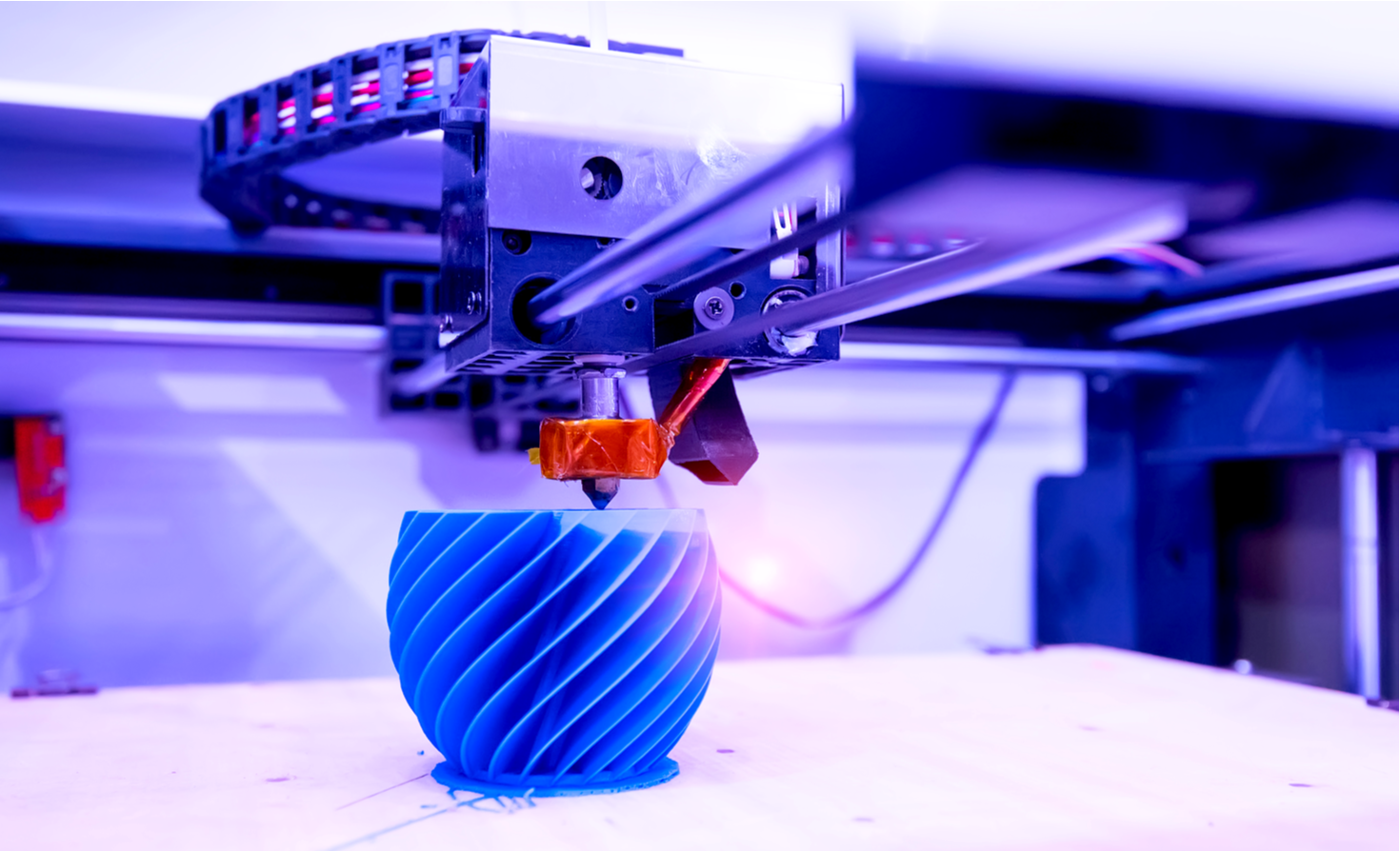

Rapid prototyping

Create a 3D model of scale size using rapid prototyping services that will help the next presentation.

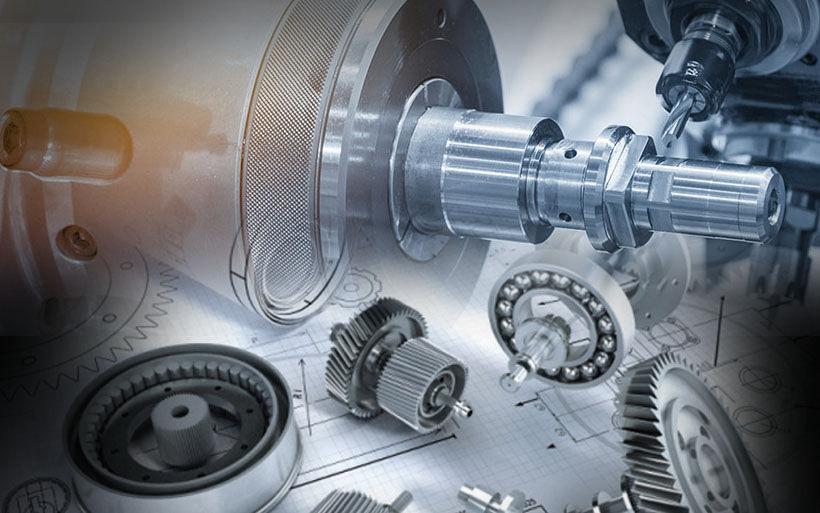

CNC machining

Test the function and fitting of the parts by making quick metal or plastic-based prototypes.

Vacuum casting

Get prototypes made of polyurethane using silicone mold for marketing research and other exhibition purposes.

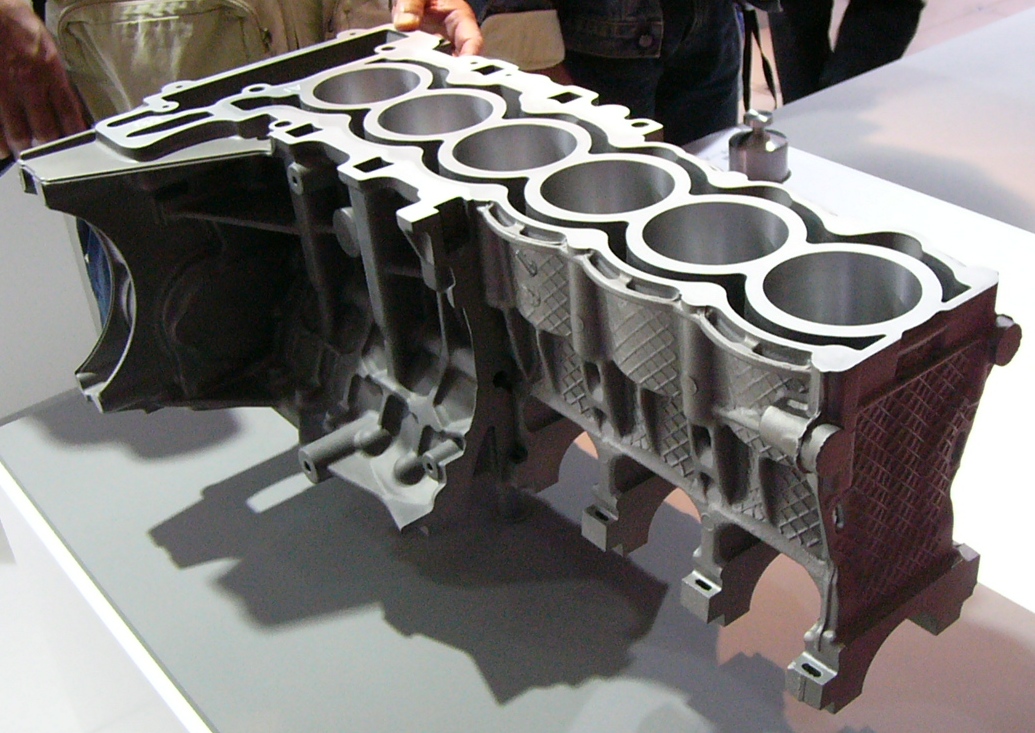

Rapid tooling

Test the parts before mass production with real material prototypes. This method is appropriate to give a test production of 100-150 units.

3D Printing

Injection molding

Get a head start on the mass production of plastic-based parts and objects with injection molding.

Finishing Services

Get well-finished mass production with the finishing services that include chrome finishing, powder coating, painting, etc.

About Going

We are here to help and ensure that your project is a success with complete prototyping backing and visualization for the next investor. As a market leaders in the prototyping industry with a highly talented workforce, we will help you in creating the perfect prototype in less time and with a dedicated team.

Become an expert

Prototyping is something that is one of the most crucial angles of the manufacturing niche. We are here to help you become the expert in your industry with complete guidance throughout the process. Get the right prototype that suits your project and market research.

Going Rapid Prototyping

Rapid prototyping is the best way to make your idea become the reality. This technique helps in exploring and realizing your thoughts more quickly. Going Rapid makes full use of it to test the requirements of the market, evaluate the figures of products and improve the design all the time.

Captain of CNC Machining

Bright Spots of Rapid Tooling

The bright spots of rapid tooling lie in its machining process and materials. There are increasing people opting for rapid tooling because it has the ability to test the production and ensure they could get parts as desired. Its production capacity can be varied with the requirements and times. Also, new parts and products can be launched in short time to market.

“

My entire team was prototyping by the end of the first day!

We desperately wanted help with our prototyping, since we had no clue where to start and where to go. We are grateful that we came across Going Rapid for our prototyping. Not only did they deliver the prototypes in time, but they also helped users understand the process.

John Smith

FAQ

It is appreciated be asked if you have any doubts. These are some common questions raised by our clients, along with our answers which will help you to choose the best for your project.

Can I get a quote for the order?

Yes, we will provide an in-detail quote for the order. It can take around 3-5 days for us to get back to you.

What is the usual timeline for the delivery of the parts?

The usual timeline for the delivery of the parts depends on the complexity of the project. The simpler parts take 2-3 weeks, and complex ones can take more time.

Can I order passivation for the metal parts?

Yes, we provide passivation for the metal parts. In this process, the surfaces of the metal parts are protected by changing their chemistry.

What is required to get a quote?

To get a quote, you will have to submit both 3D CAD files and 2D drawings in IGES/STEP format and PDF format, respectively.

What is the material used for manufacturing the prototypes?

We use varying materials for manufacturing, ranging from metals to plastics. The parts will be created according to the specifications sent to us.

What is the company’s confidentiality policy?

We take special care of the client’s project’s confidentiality as we strictly follow the non-disclosure clause of the agreement. By all means, we keep the proprietary information safe.

Design Tips

Read the tips of prototyping and succeed in creating an impressive model that will impress the consumers and investors.

Case Studies

We have stories and case studies of small and big businesses from automobile to consumer products to aeronautics industries, reaching their goals with accurate prototyping.

Ready to start your next project?

Contact us and get a quote in 24 hours.