CNC machines have become mainstream in the race of manufacturing efficient and precise products. Its highly effective and efficient results are the main elements that make it more useful. Previously, we have discussed the advantages and applications of CNC machines.

In this article, we will discuss the main components, types, and working of the CNC machines. Let’s get started.

Types Of CNC Machines:

Different types of CNC system machines include

- CNC milling machine:

This machine is useful to make holes, create bores and slots in the products. Spur gears are also manufactured with this machine. To work with it G codes and M codes are inserted in the machine so that it can work according to the given programming commands.

- CNC laser cutting machine:

As it is mentioned in the name, it uses a laser to carry out the cutting process. It is highly effective and precise as compared to conventional methods of laser cutting machines.

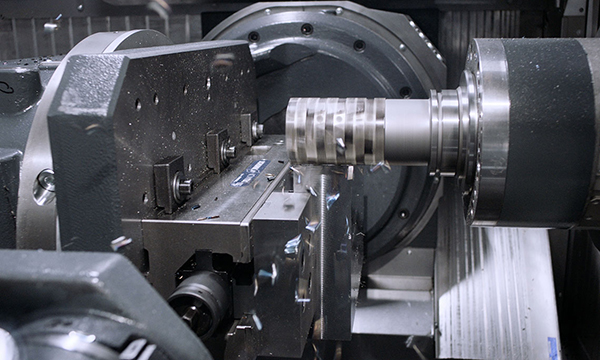

- CNC lathe machine:

CNC lathe machine has vast uses in the industries for quick production of products. Engineers create a programming command that is inserted in the memory of the CNC lathe machine.

If you want to repeat the process, you would not need to change the programming again, the previously inserted memory will repeat the process.

- CNC plasma cutting machine:

CNC plasma cutting machines have a similar working process as CNC laser cutting machines. This machine penetrates the hardest materials by a plasma torch. It is used for materials that are not be cut with laser cutting machines.

- CNC EDM (Electric Discharge Machine):

It is also known as the spark CNC machine as it removes the material from the surface of the product with the help of electrical sparks.

The whole process is done by the programming commands. So it gives a great surface finish as compared to the conventional machines.

5 axis cnc machines*

Components Of CNC Machines:

A CNC Machine has five main parts. Let’s read about them.

- MCU or Memory Controlled Unit

It can be called the brain of the machine. MCU receives the information and makes all the decisions according to that data.

- Drive Unit

Electrical energy is converted into mechanical energy that helps to drive the axis.

- Feedback Devices

It measures the displacement or distance of the axis. The feedback device works in a cycle with MCU and Drive Unit.

- Minicomputer

The programming commands are filled in the minicomputer using a keyboard.

- Some Manual controls

Loading, unloading, switching on or off are manual controls.

Working Of CNC Machines:

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) are the two main software. The first one enhances the quality of the product and CAM manufacturers according to the G and M codes.

The programs written are fed into the MCU with the help of floppy discs and memory cards.

The input data is sent to the MCU. Here it is converted into a binary system.

After that, it goes to the driving system to control the movement of components.

The MCU calculates the work being done to the actual work and tells the difference. The difference is sent to the machine tool to complete the rest of the operation.