Die Casting

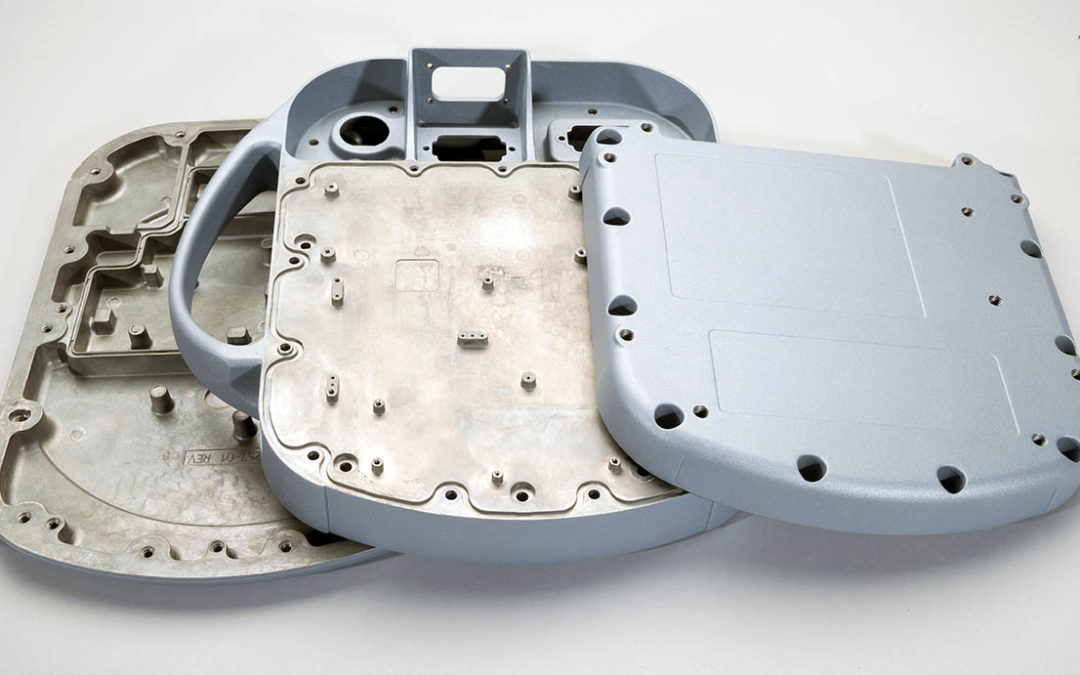

Smaller parts and prototypes should be perfect and accurate in all its factors. Our die casting service will help get the right parts for both market research and smaller production runs.

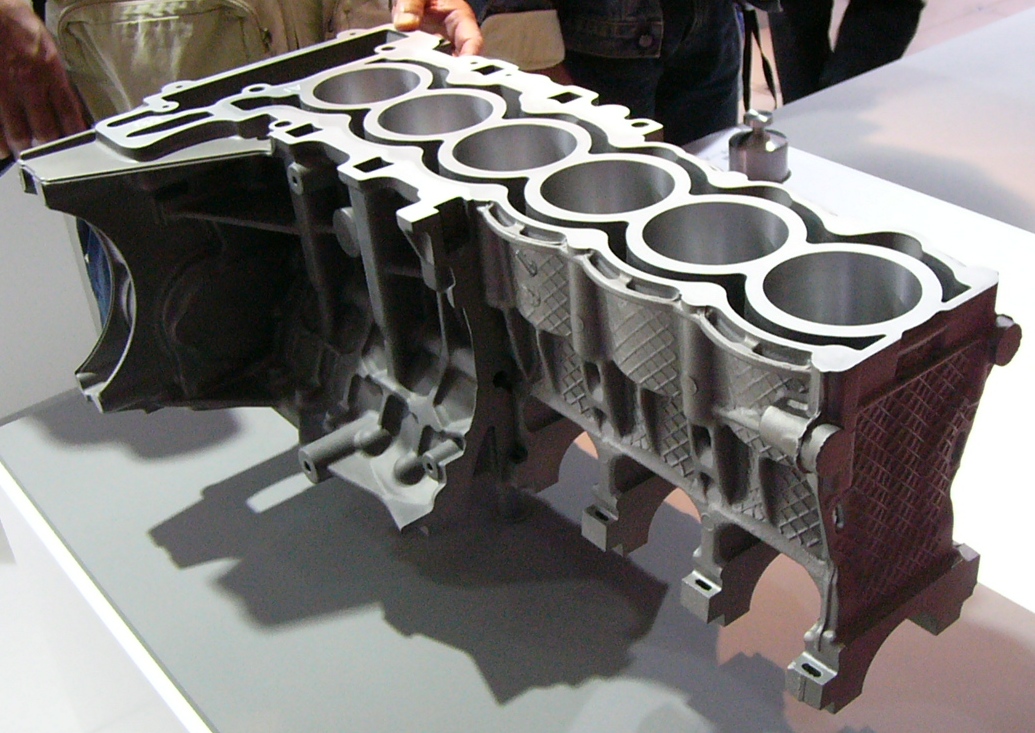

Die casting

Going Rapid will help you get the exact metal parts that you want for both testing and production purposes. We have advanced tools and machinery, including hot chamber casting and cold chamber casting machines for varied production.

Stability

The parts created by the die casting process of injecting metal into molds hold more stability.

The heat resistance and stability of the part under pressure are more in die casting. Our team of experts will help achieve the exact dimension of the castings using the die made of steel.

The heat resistance and stability of the part under pressure are more in die casting. Our team of experts will help achieve the exact dimension of the castings using the die made of steel.

High speed

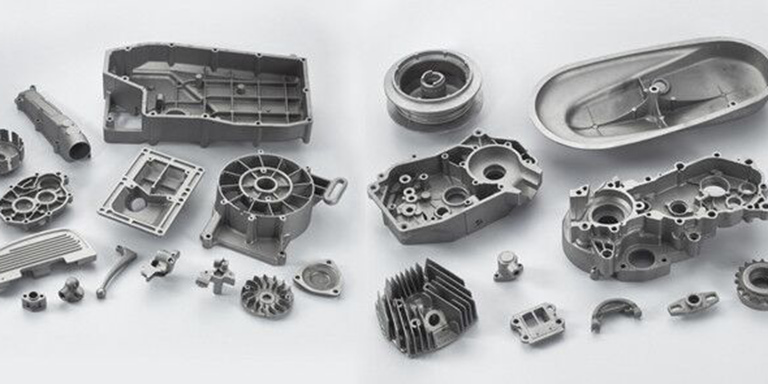

Our team of die casting will provide the complex parts of varying dimensions in lesser time.

The metal dies can be used both for prototyping and for small call mass production, without losing the mold’s usage. Also, the assembly of the parts becomes much easier.

The metal dies can be used both for prototyping and for small call mass production, without losing the mold’s usage. Also, the assembly of the parts becomes much easier.

Better finishing

The end product created with the die casting process has much more stability and better finish.

Metal dies are much stronger and thus are better than plastic molding. Not only will the parts be more accurate, but they will also have a better finishing than any casting method.

Metal dies are much stronger and thus are better than plastic molding. Not only will the parts be more accurate, but they will also have a better finishing than any casting method.

Design Tips

Read the tips of prototyping and succeed in creating an impressive model that will impress the consumers and investors.

Case Studies

We have stories and case studies of small and big businesses from automobile to consumer products to aeronautics industries, reaching their goals with accurate prototyping.

Ready to start your next project?

Contact us and get a quote in 24 hours.