In new product development, the success or failure of the prototype depends on the choice of rapid prototyping technique. There are various techniques to choose from when it comes to prototyping. It can range from a cardboard mockup to a fully functional part that resembles the finished product.

Prototyping is vital in any product design, especially in developing a new product. It involves different processes to make a rough model of the product, to test its shape, size, and functionality.

In this article, we will discuss the key factors that impact your selection of the best prototyping method that you can use in your prototyping process. Let us go over them one by one.

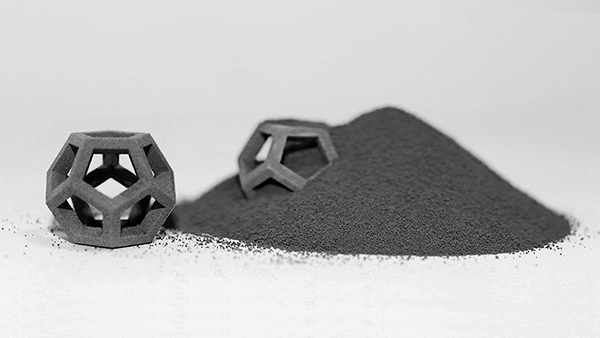

3D printing parts and materials*

5 Factors to Consider in Selecting Your Rapid Prototyping Technique

Prototypes can vary since each project, product design, and product differs. The success of the rapid prototyping process depends on the selection of what technique to use. Here are the five factors that you need to consider when choosing the right technique for your next prototyping process.

Purpose

Product design and development are meant to fulfill four purposes: learning, communication, integration, and milestones. As you well know, the purpose of prototyping varies depending on the stage of new product development you are right now. Each of these stages has its feature and functionality to mitigate risks.

Quality

The accuracy or precision of a product will dictate the process and the finishing you need. In addition, the quality of the prototype in comparison to the final product should also be considered.

As the cost of high-fidelity prototypes costs more, they should also be considered when considering the return on investment. The life of the prototype is also crucial in deciding the technique. One example is when the part requires a fastener that will be used frequently. This part needs metal or machined inserts made with CNC machining instead of 3D printing.

Another factor that affects the selection of techniques in rapid prototyping is material selection. It plays an important role in the quality of the prototype.

Quantity

The number of prototypes you need is essential in deciding the prototyping process. This is because the prototyping technologies are cost-effective in smaller quantities. In additive manufacturing, the quantity of parts needed plays a vital role in costing as high-volume would need more time to produce than small quantities.

Complexity

The complexity of a part and the delicate details of its feature also dictates the type of rapid prototyping process to be selected. 3D printing, for example, is perfect for producing parts with complicated small parts. However, it may not be ideal for the final product because it is costly.

Cost

Finally, the last factor to consider in choosing your rapid prototyping technique is your resources. We are talking about the time, money, and the number of hours needed to get the prototypes manufactured.

One of the things to consider is the time consumed in post-processing when choosing between low-quality prototypes and high-quality prototypes. Another is when using 3D printing. You may need to use finishing techniques, although it is cheaper and quicker.

Conclusion

Product development always involves creating prototypes using various techniques to test the ideas, functionalities, etc. The quality of your testing and the final selection of the technique to use depend on how well you want the prototype to closely resemble the final product.